Payload Sand And Slurry Pump

Efficient Dredging with the Payload Electric Sand & Slurry Pump

The DAE Pumps Payload Electric Sand & Slurry Pump stands out as a robust and reliable solution for dredging and transporting solids. Engineered to handle demanding conditions, this pump can move up to 2000 cubic meters of solids per hour. Its advanced non-clogging suction mechanism can manage up to 3.9 inches in diameter, effectively transporting up to 30% solids through a 16-inch discharge.

Versatile and Powerful Pumping Solution

Part of the DAE Pumps submersible sand and slurry pump series, the Payload electric slurry pump is a versatile asset for various dredging operations. It can be customized to meet specific project requirements, whether deployed via cable or mounted on an excavator. Optional features, such as an agitator or water jetting ring, enhance its capability to handle organic materials like seaweed and grass, ensuring optimal suction performance.

Key Features of the Payload Electric Sand & Slurry Pump

- Highly Durable and Abrasion Resistant Dredge Pump

- Multiple Size Pump Options: 3″, 4″, 6″, 8″, 10″, 12″, 14″, and 16″

- Capacity: Up to 2000 Cubic Meters Per Hour

- Solid Handling: Pumps up to 30% Solids

- Operational Depth: Up to 250 meters

- Robust Electric Motor: Provides strong torque and long life

Specifications

- Max Capacity: 2860 GPM (650 m³/h)

- Max Head: 89.5’ (27m)

- Impeller Diameter / Type: 16” (405mm) / 3 Blades Closed

- Discharge Size: 12” (300mm)

Solid Handling: 3.6” (90mm)

Materials

- Casing: Spheroidal Cast Iron EN-GJS500-7 (EN 1563)

- Motor Housing: Cast Iron EN-GJL-250 (EN 1561)

- Wear Parts: High Chrome EN-GJN-HV600 (XCr18) (EN 12513)

- Main Shaft: High Tensile Steel 39NiCroMo3 (AISI 9840)

Motor

- Motor Displacement: 9.8 cu. Inch (160 cc)

- Max. Oil Flow Rate: 72 GPM (270 l/min)

- Max. Pressure: 4351 PSI (300 bar)

- Power: 185 HP (475 kW)

Speed: 1450 RPM

Seals / Lubricant

- Motor Side Seals: 2 Lip Seals (BUNA)

- Impeller Side Seals: 5 Lip Seals (3 BUNA + 2PTFE) + 1 V-ring (TPU)

Oil type: ISO 320

Pump and Dredge Hub

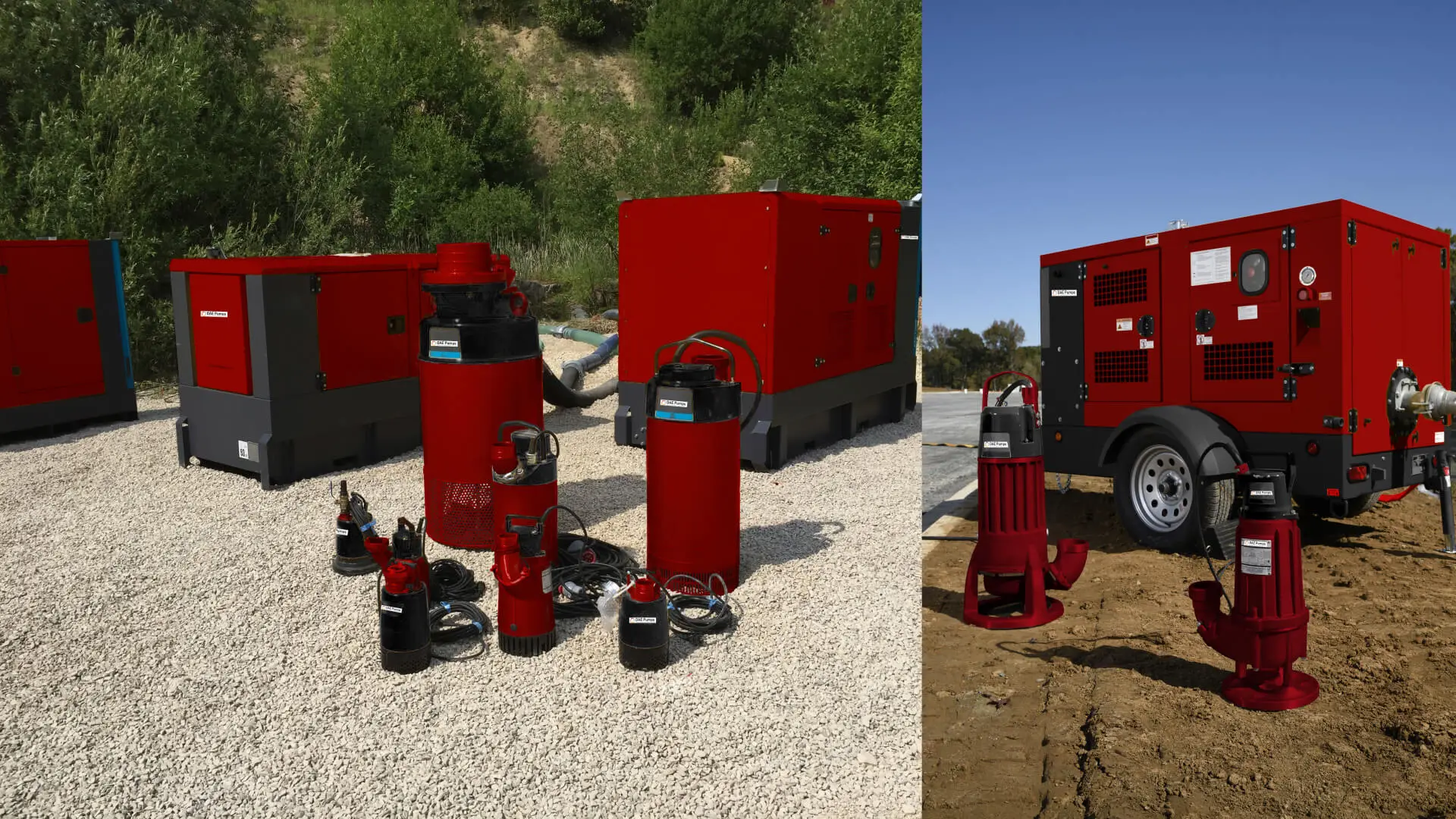

Comprehensive Dewatering Solutions Tailored to Your Needs

At DAE Pumps, we design our pumps with performance, ease of use, and maintenance in mind. Known for their long-lasting durability and operational efficiency, our pumps feature sealed and modular components that simplify usage and servicing. These attributes ensure consistent operation and straightforward maintenance, enhancing productivity and user satisfaction.

Dewatering Pumps

Discover our extensive selection of dewatering pumps, perfect for various applications in Libya, including irrigation, fountains, and liquid transfer tasks. Renowned for their exceptional performance, our pumps are synonymous with reliability and cost-effectiveness, ensuring efficient operation in every scenario.