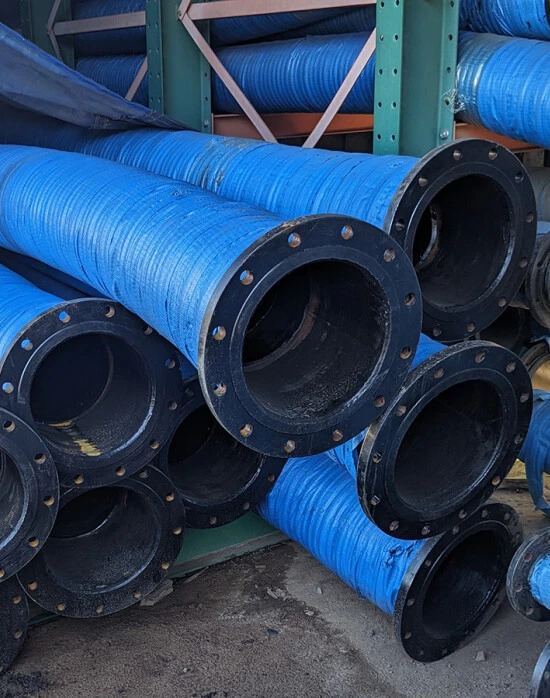

HDPE Pipes

Advanced HDPE Pipe Solutions by Anaconda Pipe and Hose

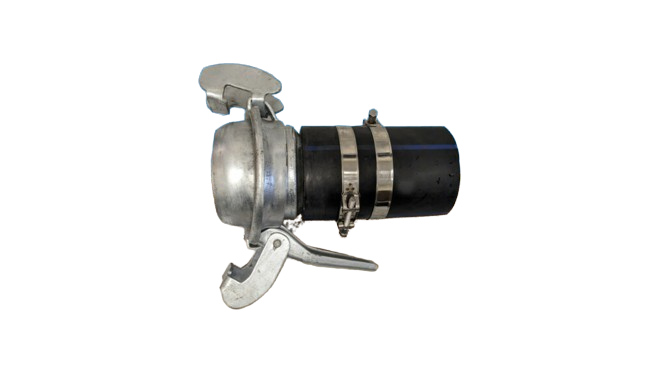

Innovative Bauer Couplings:

Each Anaconda HDPE pipe is equipped with Bauer couplings, which are distinguished by their adaptability and cost-efficiency. These modular fittings enable swift and effortless adjustments, significantly reducing the time and labor required for pipe connections and disconnections.

Comprehensive Thickness Options:

Anaconda provides HDPE pipes in three distinct thickness grades: DR11, DR17, and DR26. This selection ensures you can find the perfect fit for your project’s demands, enhancing performance across various applications.

Rent or Purchase Flexibility:

Unique among North American manufacturers, Anaconda Pipe & Hose allows customers to rent or purchase HDPE pipes. This flexibility helps manage costs effectively, with rental options available for short-term needs (please inquire for specific terms).

Tailored Customization:

Anaconda Pipe and Hose offer extensive customization possibilities for their HDPE pipes. Clients can specify the desired diameter, length, and material composition, tailoring their selections to meet precise industrial requirements.

Diverse Industrial Applications:

Designed for multifunctionality, Anaconda HDPE pipes are ideal for transporting fluids, handling chemicals, and supporting various industrial fluid systems. Their robust construction ensures reliable performance in diverse operational environments.

Seamless Fitting Integration:

Anaconda HDPE pipes are engineered to connect flawlessly with various fitting types, including threaded connections, Bauer fittings, ANSI flanges, and multiple couplings, ensuring durable and leak-proof installations.

As the official distributor in Libya, Pump, and Dredge Hub proudly offers Anaconda Pipe and Hose’s superior HDPE pipe solutions, providing unparalleled quality and innovation to meet the demands of your industrial projects.

Engineered for Industrial Excellence

One of the key features that sets Anaconda Pipe & Hose’s industrial HDPE pipes apart is their ease of connection and disconnection. Featuring Bauer fittings, these pipes enhance modularity and allow for quick adjustments to meet dynamic project requirements. Crafted from high-quality materials, they are designed for durability and are capable of withstanding harsh environments thanks to their high-pressure tolerance and temperature resilience. Additionally, the pipes boast exceptional corrosion resistance due to protective coatings, extending their lifespan and maintaining performance in corrosive settings.

Precision in construction ensures that Anaconda HDPE pipes have exact dimensional accuracy, facilitating seamless integration with other fittings and reducing potential leaks. These pipes offer a balance between flexibility, allowing for versatile installation configurations and rigidity, ensuring structural integrity under operational stresses. Rigorous quality assurance processes, including stringent testing and compliance with industry standards, underscore Anaconda’s commitment to delivering reliable and robust piping solutions supporting various industrial processes.

Bauer Fittings: Enhancing Industrial Pipe Systems

Bauer fittings, known for their quick-connect capabilities, are a cornerstone in industrial pipe systems across various sectors, including wastewater, irrigation, construction, and mining. These fittings, often called Bauer Couplings, offer rapid and secure connections, significantly reducing downtime and ensuring leak-free operations that bolster system reliability and environmental safety.

The versatility of Bauer fittings is evident in their ability to adapt to different pipe materials and sizes, making them an ideal solution for diverse fluid transport needs. Constructed from durable materials like high-quality galvanized or stainless steel, these fittings are designed to withstand harsh industrial environments, extending their service life and reducing replacement frequency. They feature a reliable sealing mechanism that guarantees a tight, leak-proof connection across a range of fluids, including harsh chemicals and slurry, and their pressure adaptability allows for use in various pressure conditions.

Bauer fittings also excel in user-friendliness; their quick-locking mechanism facilitates easy operation, making pipe system management more efficient. Additionally, their interchangeability across different brands and materials enhances system flexibility, simplifying maintenance and repairs without the need for pipe fusing or welding. This, combined with their reduced maintenance needs and the cost-effectiveness they bring, makes Bauer fittings a preferred choice for companies seeking efficient and safe fluid handling solutions. The availability of various accessories further enhances the functionality and customization potential of these fittings, ensuring they meet the specific needs of each application.

The Benefits of Using Straight Lengths of HDPE Pipes Without Fittings

In some industrial scenarios, choosing straight lengths of HDPE pipes without fittings instead of incorporating various fittings offers several technical and operational advantages. This approach enhances the efficiency and effectiveness of fluid systems by providing a smoother flow path. By eliminating fittings, there are fewer abrupt directional changes, reducing friction and turbulence and improving flow dynamics and efficiency.

Utilizing straight pipe lengths simplifies both maintenance and installation processes. With fewer components that could fail or wear out, maintenance becomes less frequent and less complicated, significantly decreasing long-term costs and operational disruptions. Similarly, the installation process is streamlined since straight lengths are easier to handle and align, potentially reducing labor costs and time, especially in extensive piping networks.

Moreover, the pipeline’s structural integrity is enhanced by the continuous, uniform nature of straight lengths, which is crucial in environments where stability and resistance to external forces are vital. The reduced number of connections also minimizes the risk of leaks, an essential factor in systems that handle hazardous materials or where absolute leak prevention is paramount.

In addition to practical advantages, opting for straight lengths can lead to cost savings, depending on the project’s specific requirements and constraints. This configuration can be particularly beneficial in specialized applications where the design does not necessitate fittings due to the nature of the fluid, pressure requirements, or other system-specific factors.

While there are clear benefits to using straight lengths without fittings, evaluating whether this approach is suitable for a particular project based on its specific requirements, industry standards, and regulatory considerations is important. In frequent connections and disconnections, the benefits of fittings such as Bauer or ANSI may outweigh the advantages of using straight lengths. Consulting with engineering experts and adhering to industry best practices are crucial in making well-informed decisions about the most appropriate piping configuration for any application.

CONTACT US

Ready to Simplify Your Piping System?

Discover the advantages of using straight lengths of HDPE pipes without fittings for your next project. Enjoy enhanced flow efficiency, reduced maintenance, and streamlined installation processes. Connect with our experts today to explore how our HDPE solutions can meet your specific needs and maximize your operational efficiency.

Pipes and Hoses

Please browse our extensive selection of resilient and durable pipes and hoses, engineered to withstand harsh conditions and available in various diameters and mounting styles across Libya. These products consistently deliver excellent performance in extreme operating environments. Discover custom solutions for your fluid transportation needs with our comprehensive product range today. Our pipes and hoses are built to last, ensuring long-term efficiency and cost-effectiveness for all industrial applications.