A dredging machine is a specialized piece of equipment designed to remove sediment, debris, and other materials from the bottom of rivers, lakes, harbors, and other bodies of water. Its core function is to maintain or increase water depth, support infrastructure development, and assist in environmental cleanup. Over time, the technology behind the dredging machine has undergone significant evolution. What began with manual labor and basic buckets has transformed into highly advanced systems equipped with hydraulic pumps, GPS guidance, and remote operation capabilities.

Dredging tools and techniques have also advanced, enabling more precise and efficient sediment removal in a wide range of environments. Modern dredging equipment encompasses a range of mechanical and hydraulic systems designed to meet various site conditions and project requirements.

Today, dredging is more relevant than ever. Growing urbanization, industrial expansion, climate resilience efforts, and environmental restoration projects all depend on reliable dredging solutions. This blog will explore how dredging machines are used today, the types of dredging equipment and tools involved, and the innovations driving the industry forward.

Key Components of a Dredging Machine

A modern dredging machine is a complex system composed of several key components, each playing a crucial role in the efficient removal and transport of sediment. At the heart of most hydraulic dredges is the cutter head, a rotating tool that loosens compacted sediment and directs it toward the suction inlet. The suction system then draws the material into a pipeline, powered by a high-efficiency dredge pump. Once inside the system, the slurry is transported through a discharge pipeline, which directs the dredged material to designated disposal sites, barges, or reclamation areas.

In addition to the main components, various dredging tools support the stability and performance of the operation. Winches and anchors are used to position and maneuver the dredging machine accurately. Spuds are vertical piles that anchor the dredge in place during operation. Booster pumps, often located along extended discharge lines, help maintain pressure and slurry flow over long distances.

Dredging equipment can vary widely depending on the type of dredging being performed. Mechanical dredging machines, such as clamshell or backhoe dredgers, use buckets and grabs for direct excavation and are best suited for compact materials or confined areas. In contrast, hydraulic dredging equipment utilizes suction and fluid power to move sediment, making it ideal for larger volumes and softer soils, such as those found in rivers or coastal projects.

Modern advancements have further enhanced dredging performance through the use of automation and remote-control technology. Many dredging machines are now integrated with GPS systems, sonar sensors, and onboard software that enable operators to monitor depth, positioning, and material removal in real-time. These innovations not only enhance precision and safety but also reduce labor requirements and operating costs.

Understanding these components and supporting dredging tools is essential for selecting the right dredging equipment for specific applications and achieving maximum operational efficiency.

Core Applications of Dredging Machines in Today’s World

Dredging machines are essential to a wide range of modern infrastructure and environmental projects. Their versatility and adaptability allow them to be used across various sectors, each with unique operational demands and site conditions.

A. Harbor and Port Maintenance

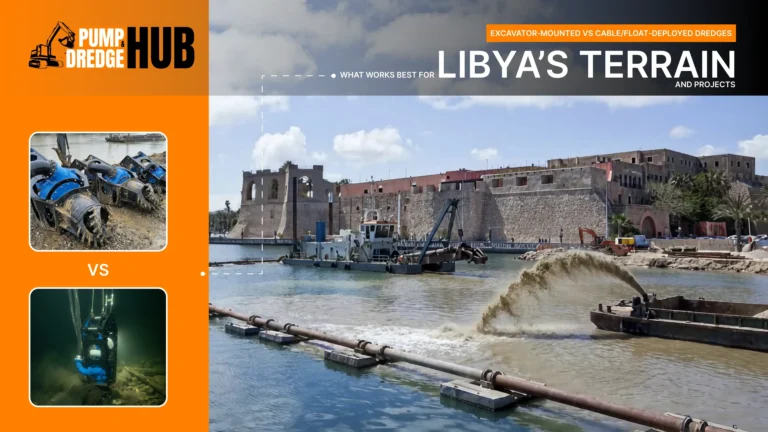

One of the most critical applications of a dredging machine is maintaining harbor and port depth to ensure safe and efficient navigation. Sediment accumulation in busy shipping channels can restrict vessel access and disrupt commercial operations. In these high-traffic areas, specialized dredging tools such as clamshell buckets or cutter heads are used to remove sediment quickly and precisely. Routine dredging helps preserve navigability and supports the continued flow of global trade.

B. Land Reclamation and Coastal Development

Land reclamation projects utilize large-scale hydraulic dredging machines to extract vast quantities of sand and sediment from seabeds and transport them to designated fill areas. These projects extend coastlines, create new land for construction, or restore eroded shorelines. Booster pumps and other dredging equipment are essential in transporting materials over long distances, making this application one of the most equipment-intensive in the field.

C. Environmental Remediation

Dredging machines are widely used in environmental cleanup efforts, especially where water bodies have been contaminated by industrial waste or urban runoff. In lakes, rivers, and nearshore zones, precision dredging equipment is deployed to remove toxic sediments without disturbing the surrounding ecosystem. Modern dredging tools equipped with sensors and automated controls ensure targeted sediment removal with minimal environmental disruption.

D. Flood Control and Waterway Management

Urban and rural areas rely on dredging machines to clear debris and sediment from rivers, canals, and drainage systems, thereby reducing flood risk. In these settings, mobile and compact dredging machines offer access to hard-to-reach areas and are often preferred due to their maneuverability and ease of deployment.

E. Mining and Resource Extraction

In mining, dredging machines are used to extract valuable resources, such as sand, gravel, and minerals, from riverbeds or coastal areas. Rugged dredging tools are designed to handle abrasive materials, and the associated dredging equipment is built for continuous, high-volume operation in harsh conditions.

These diverse applications underscore the crucial role of the dredging machine and its supporting tools in shaping contemporary infrastructure and environmental management.

Specialized Dredging Tools and Equipment for Different Environments

Different environments demand tailored solutions, and specialized dredging tools and equipment are essential for maintaining efficiency and safety across diverse project sites. Whether operating in remote wetlands or dense urban centers, the right dredging machine makes a significant impact on performance and environmental protection.

Amphibious dredging machines are designed to operate in marshes, wetlands, and other soft-ground environments where standard equipment would sink or become immobilized. These machines are equipped with pontoons or tracks that allow them to float or crawl through shallow, muddy conditions. Their ability to transition between land and water makes them indispensable for ecological restoration, levee maintenance, and floodplain management. In these applications, supporting dredging tools such as spuds, hydraulic cutters, and GPS guidance systems are often used to enhance control and accuracy.

For deepwater or confined spaces, submersible dredge pumps are commonly deployed. Mounted on cranes, excavators, or cable systems, these pumps serve as an extension of larger dredging machines, enabling operators to remove sediment from greater depths or hard-to-reach areas. This type of dredging equipment is vital for underwater mining, harbor maintenance, and deep-channel excavation where standard surface-level machinery would be ineffective.

Urban water bodies and narrow canals require a compact dredging machine and maneuverable dredging tools to navigate tight spaces without damaging surrounding infrastructure. These machines are typically electric or diesel-powered and operate with precision cutter heads or auger attachments. Their use is common in cities for sediment removal from drainage channels, stormwater systems, and small reservoirs.

In remote or emergency scenarios, portable dredging equipment becomes essential. These compact systems are easy to transport and assemble, making them ideal for disaster response, temporary projects, or seasonal work. A portable dredging machine can be deployed quickly to remove blockages, restore flow, or address localized sediment issues with minimal setup.

Together, these specialized solutions demonstrate how adaptability in dredging machine design, combined with the right dredging tools and equipment, ensures successful outcomes across a wide range of environmental conditions.

Industry Trends and Technological Advancements

The dredging industry is undergoing a significant transformation, driven by advancements in technology and a growing focus on environmental responsibility. Modern dredging machines are no longer limited to manual operation—they are now equipped with smart systems that enhance precision, efficiency, and safety across various dredging applications.

One of the most notable developments is the use of remote-controlled and autonomous dredging machines. These systems enable operators to remotely control dredging activities, thereby reducing the need for onsite personnel in hazardous or hard-to-access environments. Autonomous dredging machines, guided by pre-programmed parameters and environmental data, can perform sediment removal with consistent precision and minimal human intervention. This technology not only boosts productivity but also enhances worker safety and operational continuity.

Real-time monitoring and GPS-enabled systems are also becoming standard features in modern dredging operations. These technologies provide live data on dredge head positioning, sediment volume, water depth, and environmental conditions. Operators can make real-time adjustments to dredging parameters, optimizing efficiency while minimizing the risk of over-dredging or disturbing protected zones. This level of control is particularly valuable in sensitive environments and large-scale projects where accuracy is critical.

Environmental considerations are shaping the future of dredging, leading to the rise of eco-friendly dredging equipment and low-impact tools. Newer dredging machines are being designed to reduce turbidity, minimize fuel consumption, and prevent contamination. Biodegradable hydraulic fluids, quieter engines, and emissions-reducing components are increasingly integrated into equipment to meet sustainability goals and regulatory standards.

In addition to reducing environmental harm, the industry is placing greater emphasis on material reuse and sustainable dredging practices. Instead of viewing dredged material solely as waste, operators now explore ways to repurpose it—for example, in beach nourishment, wetland restoration, or construction fill. This shift not only reduces disposal costs but also contributes to circular economy initiatives.

These technological and environmental innovations are redefining what it means to operate a modern dredging machine. They allow companies to achieve greater precision, lower operating costs, and meet growing demands for sustainability and regulatory compliance—all while improving the overall performance of dredging equipment and operations.

Choosing the Right Dredging Machine for the Job

Selecting the right equipment for a dredging project is crucial for achieving optimal performance, cost efficiency, and environmental compliance. With a range of dredging equipment and tools available, it’s important to evaluate the specific conditions and objectives of each site.

Sediment type is one of the most critical factors to consider. Fine materials, such as silt and clay, are typically best handled with hydraulic systems that utilize suction and pipeline transport. In contrast, coarse or compacted materials such as sand, gravel, or debris often require mechanical methods that physically lift and remove sediment using buckets or grabs.

Water depth and project size also influence the selection of equipment. Shallow areas, narrow canals, or small lakes may require portable or amphibious solutions that are easy to maneuver. Large-scale operations, such as harbor deepening or land reclamation, require high-capacity systems capable of efficiently moving large volumes.

Environmental considerations must also be factored in, particularly when working near sensitive habitats, protected areas, or residential zones. In these cases, low-impact tools, turbidity control systems, and real-time monitoring can help minimize disruption and maintain compliance with regulatory standards.

When comparing mechanical, hydraulic, and hybrid systems, it’s important to weigh both performance and adaptability. Mechanical options offer greater precision for hard or varied sediments, while hydraulic systems excel in continuous, high-volume applications. Hybrid setups can provide the flexibility needed for sites with mixed material types or variable depths.

Selecting the optimal combination of dredging tools—such as cutter heads, suction pumps, booster stations, and discharge lines—can substantially enhance operational efficiency and lower overall costs. Matching these tools to the specific conditions and goals of the project ensures efficient sediment removal and maximizes return on investment. Ultimately, thoughtful equipment selection is the foundation of a successful and sustainable dredging operation.

Tailored Dredging Solutions for Modern Challenges

Dredging continues to play a vital role across a wide range of sectors, from maintaining busy ports and reclaiming coastal land to restoring ecosystems and supporting flood control efforts. As applications expand, so does the need for adaptable and efficient dredging solutions that match specific site conditions and project goals.

Pairing the right equipment and tools with each unique dredging challenge is essential to maximize efficiency, control costs, and ensure long-term success. Whether the task involves high-capacity sediment removal or precise environmental cleanup, careful selection of technology and method is key.

Beyond operational benefits, dredging supports sustainable infrastructure and environmental stewardship. With advancements in eco-friendly equipment and smarter technologies, today’s dredging practices are better equipped than ever to strike a balance between productivity and responsible resource management, as well as ecological protection.