Disc Centrifugal Slurry Pumps

Enhanced Operation of Apex Filter Press Pumps with Advanced VFD Technology

Apex Filter Press Pumps are meticulously designed to accommodate a wide range of filter press sizes, incorporating advanced Variable Frequency Drive (VFD) technology. This technology enables variable speed operation, starting with high flow rates and low pressure to initiate the filter cake formation. This initial phase is crucial as it prevents premature clogging of the filter cloth by avoiding the early formation of a dense, impermeable layer of solids.

Throughout the filter press filling cycle, the VFD controller works harmoniously with the pump, automatically and progressively increasing the feed pressure. This gradual pressure increase, adjustable based on the slurry characteristics and solids concentration, ensures optimal filtration efficiency.

Typically, the process begins at a low pressure of 25 PSI and ramps up to a shut-off pressure of approximately 100 PSI, depending on the specific requirements of the filter press. Once the target pressure is achieved, the pump shuts off automatically, ensuring precise and efficient operation.

This automated pressure adjustment enhances filtration efficiency and extends the lifespan of the filter cloths by preventing clogging and ensuring consistent filtration quality. The flexibility of the Apex VFD system allows for seamless integration with any existing or new filter press setup, making it a versatile solution for improving industrial filtration processes.

Low NPSH Requirement for Optimal Performance

In demanding environments like those in Libya, pumps often face challenges related to variable pressure distribution caused by vanes moving through fluids. This can lead to cavitation, particularly at the point of lowest static pressure, typically at the vane outlet. The Apex Disk Pump, however, features disk impellers with inherently low Net Positive Suction Head Required (NPSHR) characteristics. The Apex impeller is also equipped with an integral axial flow inducer that further enhances its low NPSH capabilities, making it an exceptionally robust solution for challenging applications managed by Pump and Dredge Hub in Libya.

The Apex Disk Pump is meticulously engineered to generate a uniformly tangential pressure field across the system, ensuring that the only pressure gradient present is positive. This uniformity is essential for maintaining the pump’s efficiency and longevity, especially in regions with severe operational conditions like Libya.

Optimized Performance with Highly Viscous Liquids

Handling highly viscous liquids often poses significant challenges for traditional vaned impellers, reducing efficiency and capacity and increasing NPSH requirements. Viscous fluids, especially those around 500 SSU, can drastically diminish the performance of conventional impellers.

In stark contrast, the Apex Disk Pump excels in managing highly viscous fluids without suffering these performance drawbacks. The pump’s innovative design ensures proper disk spacing to accommodate fluids of varying viscosities. This unique feature allows the Apex Disk Pump to efficiently handle fluids with viscosities ranging from as low as water to as high as 400,000 SSU.

Furthermore, the Apex Disk Pump’s design ensures that flow characteristics adapt to the fluid viscosity—remaining marginally turbulent for thinner liquids and transitioning to laminar flow for more viscous substances. This adaptability significantly enhances the pump’s efficiency and guarantees consistent performance across a broad spectrum of fluid densities and viscosities, making it a versatile and reliable choice for various industrial applications.

Pump and Dredge Hub

Superior Durability Against Abrasive Liquids

Abrasive liquids containing suspended particles pose a significant challenge by rapidly wearing down pump surfaces. The Apex rotating disk pump addresses this challenge by utilizing a fluid flow design between two parallel disks, creating a boundary layer—a relatively stable, quiescent layer adjacent to the disk walls. This innovative design minimizes abrupt directional changes and rapid accelerations, preserving the protective properties of the boundary layer and significantly enhancing the pump’s resistance to abrasion. This results in exceptional durability and reliability when handling abrasive slurries, ensuring long-lasting performance in harsh conditions.

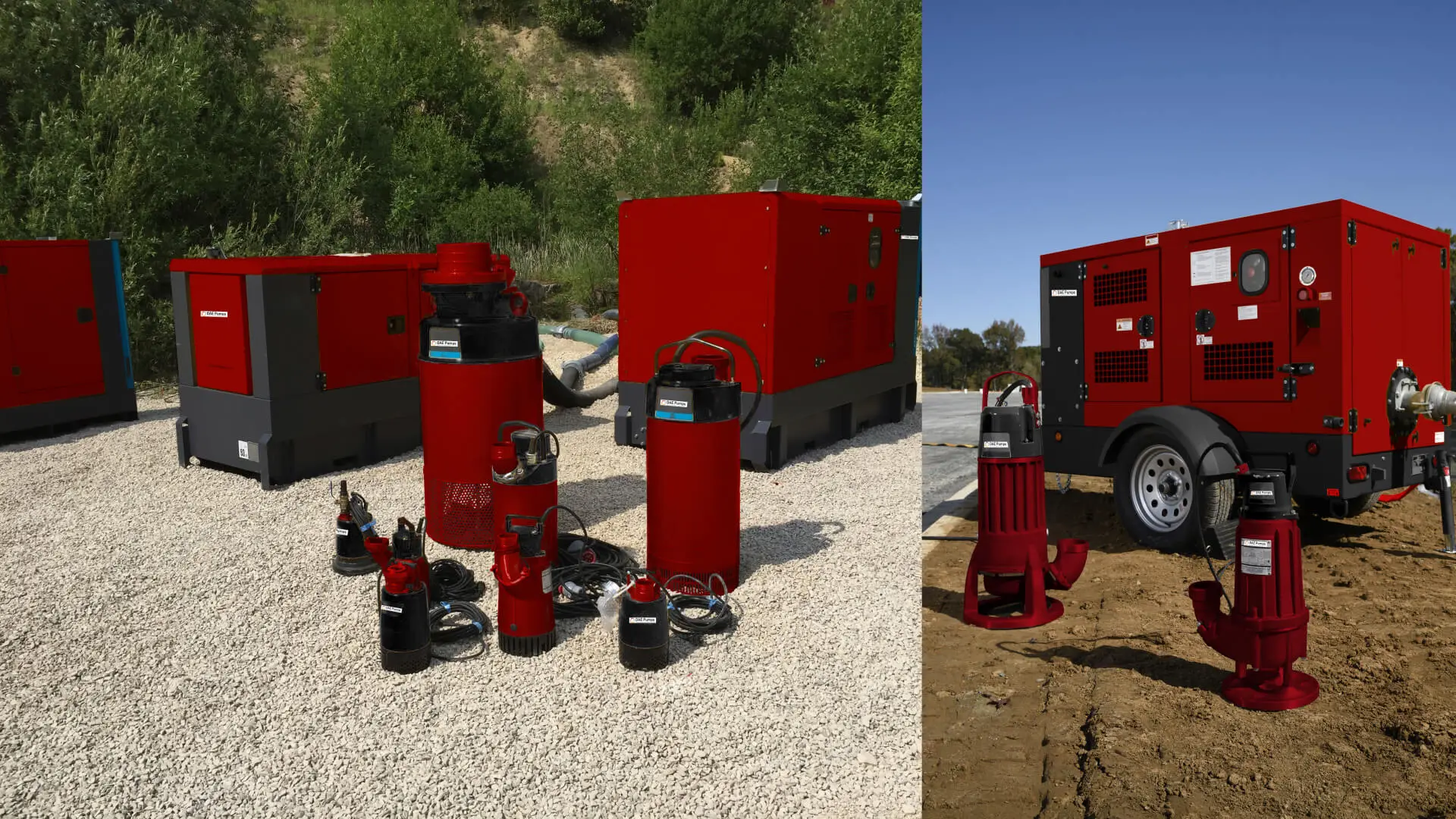

Dewatering Pumps

Discover our extensive selection of dewatering pumps, perfect for various applications in Libya, including irrigation, fountains, and liquid transfer tasks. Renowned for their exceptional performance, our pumps are synonymous with reliability and cost-effectiveness, ensuring efficient operation in every scenario.