Dredging is a crucial process in maintaining waterways, reclaiming land, and supporting various construction and mining operations. At the heart of every successful dredging operation is the dredging pump—a powerful tool responsible for transporting sediments, slurry, or other solid-laden materials from underwater beds to the surface. Without the right dredging pump, project efficiency can suffer, leading to delays, cost overruns, or incomplete material removal.

Equally critical is the choice of the overall dredging equipment system. A well-matched combination of pump, hoses, power source, and support structures ensures seamless performance under demanding conditions. For example, pairing the pump with a compatible dredging excavator can enhance mobility and access in confined or shallow areas, improving productivity on-site.

Choosing the right dredging solution involves more than just horsepower and capacity. It requires a close understanding of site conditions, sediment type, and operational goals. One of the most common decisions contractors and engineers face is whether to use a submersible dredging pump or a cutter suction dredging pump. This comparison helps determine which system aligns best with specific job site requirements, dredging excavator capabilities, and long-term operational objectives.

What Is a Dredging Pump?

A dredging pump is a specialized pump designed to transport a mixture of solids and liquids, commonly referred to as slurry, from one location to another. It is one of the most critical components in dredging operations, used to remove sediment, debris, and other materials from the bottom of bodies of water such as rivers, lakes, harbors, or mining pits. Unlike standard water pumps, a dredging pump is specifically engineered to handle abrasive and dense materials with high solid content, making it well-suited for demanding, heavy-duty tasks.

The function of a dredging pump revolves around its ability to generate enough suction and pressure to lift solid-laden fluids through pipelines over considerable vertical and horizontal distances. These pumps often feature large passages, wear-resistant materials, and high torque to withstand continuous use in harsh environments.

Dredging pumps are used across a wide range of projects. In marine construction, they assist in deepening navigation channels and ports. In mining, they are used for the removal of tailings and the transportation of minerals. Environmental dredging projects use them to remove contaminated sediments from water bodies. Dredging pumps are also essential in flood control, land reclamation, and sand extraction.

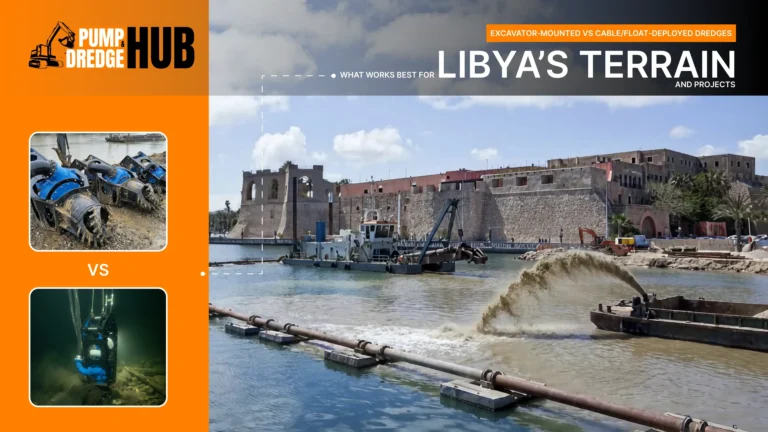

When integrated with a dredging excavator, the efficiency of a dredging pump increases significantly. The excavator offers precise positioning and mechanical support, enabling operators to access hard-to-reach or shallow areas. The dredging excavator can maneuver the pump head directly into sediment, breaking up compact material and feeding it into the suction system. This setup is commonly seen on floating platforms, barges, or amphibious vehicles.

Support from additional dredging equipment such as power units, pipelines, floats, and control systems is equally important. The entire dredging equipment system must be optimized to match the pump’s performance, ensuring consistent flow rates, minimal downtime, and reduced wear and tear.

In summary, the dredging pump is a cornerstone of effective dredging operations. Whether mounted on a dredging excavator or used in conjunction with other dredging equipment, it enables efficient removal and transport of underwater materials in some of the most demanding project conditions.

Submersible Dredging Pumps: Features and Advantages

Submersible dredging pumps are a type of dredging pump designed to operate while fully submerged in the fluid being pumped. Unlike surface-mounted pumps that rely on suction from a distance, submersible pumps are installed directly at the dredging site, allowing for more efficient and direct sediment removal. These pumps utilize an electric or hydraulic motor that powers the impeller, creating the necessary pressure to transport slurry through a discharge pipeline. Their ability to operate underwater makes them an ideal choice for deep or hard-to-access environments.

Submersible dredging pumps are widely used in various industries, including mining, pond dredging, construction, and industrial wastewater management. In mining operations, they are used to handle tailings and extract valuable minerals. In pond and lagoon dredging, these pumps provide a convenient and less disruptive method for removing sediment without draining the water body. They are also commonly used in treatment plants and manufacturing facilities to handle sludge and wastewater containing solids.

One of the major advantages of using a submersible dredging pump is its ease of deployment. Since it’s placed directly into the material being pumped, there is no need for complex suction setups or long suction hoses. This reduces overall setup time and simplifies logistics. Another benefit is the lower energy loss, as there is minimal distance between the pump and the slurry source, resulting in higher pumping efficiency.

Additionally, submersible dredging pumps require fewer pipeline sections due to their proximity to the dredging site. This minimizes frictional losses and reduces installation and maintenance costs. The design also incorporates fewer moving parts compared to traditional systems, resulting in improved reliability and reduced maintenance needs.

These pumps are often mounted on dredging excavators or pontoons, making them highly compatible with mobile dredging equipment setups. The dredging excavator helps position the pump precisely, even in shallow or remote locations, enhancing the overall versatility of the operation.

In summary, submersible dredging pumps offer a compact, efficient, and adaptable solution for a range of dredging applications. When paired with the right dredging equipment and a capable dredging excavator, they deliver reliable performance even in the most challenging environments.

Cutter Suction Dredging Pumps: Features and Advantages

Cutter suction dredging pumps are central components in cutter suction dredgers—large, powerful machines used for some of the most demanding dredging operations. These pumps are designed to work in conjunction with a rotating cutter head, which breaks up compacted or consolidated materials, such as clay, rock, or packed sand, on the waterbed. As the cutter loosens the material, the dredging pump simultaneously sucks in the slurry and transports it through a discharge pipeline to a designated disposal site.

The working mechanism of a cutter suction dredger is a coordinated system that combines mechanical and hydraulic forces to handle challenging environments. The cutter head at the suction inlet agitates the material, and the high-capacity dredging pump creates a strong vacuum to draw the mixture into the pipeline. This combination allows for uninterrupted dredging, making cutter suction pumps particularly efficient for continuous operations.

These pumps are widely used in projects involving canals, rivers, harbors, and ports. In canal deepening or maintenance, they ensure that navigable depth is maintained. In river restoration or flood control projects, they help manage sediment buildup. Port development and maintenance rely on cutter suction pumps to handle the removal of bulk materials. At the same time, land reclamation projects use them to move large volumes of sediment to fill designated areas for future construction or expansion.

One of the main advantages of cutter suction dredging pumps is their ability to handle hard or compacted materials, thanks to the powerful cutting head. This makes them especially useful in environments where standard suction or submersible pumps would struggle to operate. Additionally, these pumps support continuous dredging, which minimizes downtime and enhances operational efficiency, a crucial factor for large-scale projects that operate on tight schedules.

Another benefit is their integration into complete dredging equipment systems. Cutter suction dredgers are typically equipped with on-board power units, positioning systems, winches, and floating pipelines, all of which work in sync to ensure smooth and productive operations. This makes them a preferred choice for long-distance dredging and high-capacity material transport tasks.

In summary, cutter suction dredging pumps offer robust performance, high efficiency, and the ability to tackle tough sediment layers, making them indispensable in large-scale and high-impact dredging applications.

Key Differences Between Submersible and Cutter Suction Pumps

When comparing submersible and cutter suction systems for dredging, the choice ultimately depends on the project’s scope, material type, and operational constraints. While both are effective in their own right, they offer distinct advantages and limitations across several key factors.

In terms of mobility, submersible systems are highly portable and versatile. These units are compact and can be quickly deployed in various environments. When paired with a dredging excavator, they can easily reach confined or shallow areas, making them ideal for smaller or irregular job sites. Cutter suction systems, however, are typically mounted on large floating platforms or fixed installations. Their size and complexity make them better suited for long-term, high-volume dredging projects involving extensive dredging equipment setups.

Material handling is another significant difference. Submersible systems excel in pumping soft slurries, silts, and fine sediments. Their direct contact with the material ensures efficient intake and reduced clogging. Cutter suction systems, on the other hand, are equipped with rotating cutter heads that can break through compacted soil, clay, and rock. This makes them the preferred option for more challenging sediment removal tasks that require robust dredging equipment.

From an energy perspective, submersible setups generally require less power due to their proximity to the dredging material and the absence of long suction lines. This proximity allows for more efficient energy transfer. In contrast, cutter suction systems consume more energy due to the mechanical operation of the cutter head and the need to move material across greater distances.

When it comes to depth and distance capabilities, submersible units can be positioned deeper, especially when mounted on a dredging excavator, offering excellent vertical reach. Cutter suction systems, however, are designed for broad, open areas where extensive horizontal coverage is needed.

Maintenance is also an important consideration. Submersible systems have fewer moving parts, resulting in simpler upkeep and less downtime. Cutter suction systems require more attention, particularly for their cutter heads and mechanical components, as part of a more complex dredging equipment system.

Ultimately, selecting between these two types of dredging equipment requires a careful assessment of your project’s physical environment, sediment characteristics, and long-term operational goals.

Final Thoughts: Which Dredging Pump is Right for You?

Choosing between submersible and cutter suction systems depends heavily on the unique demands of your project. Submersible units are highly effective for smaller, more flexible operations where soft sediments are present and access may be limited. When combined with a dredging excavator, they offer excellent mobility and precise control, especially in shallow or hard-to-reach areas. In contrast, cutter suction systems are built for large-scale operations, capable of breaking through compacted materials with the help of powerful cutter heads and a fully integrated dredging equipment setup.

A key takeaway is that no single solution is suitable for all scenarios. Project requirements such as sediment type, dredging depth, discharge distance, and working environment must all be factored into the decision. Matching the right system to your project not only improves efficiency but also minimizes downtime and operational costs.

Working closely with experienced dredging equipment providers ensures that you select the most suitable setup, whether that involves standalone units or integration with a dredging excavator. These experts can assess your site conditions, recommend compatible gear, and provide insights into optimizing performance. For the best results, don’t make assumptions—consult a team that understands both the technology and the field demands of professional dredging operations.