Slurry Hoses

Dredge & Slurry Hose Solutions from Anaconda Pipe and Hose

Pump and Dredge Hub, the exclusive distributor of Anaconda Pipe and Hose in Libya, is excited to offer top-quality Slurry and Dredge Hoses. These hoses are specially engineered for superior performance in handling solids and powering through dredging tasks, ensuring exceptional efficiency, reliability, and ease of use.

Anaconda’s slurry and Dredge Hoses are built to last and crafted to withstand the demanding conditions of challenging environments, guaranteeing years of trouble-free service. As a trusted provider for various industries, these hoses deliver durability, versatility, and cost-effectiveness, allowing you to boost operational efficiency, productivity, and profitability while maintaining the highest quality standards.

Discover the advantages of Anaconda’s Slurry and Dredge Hoses:

- Strong Abrasion Resistance: Made with materials highly resistant to abrasion, these hoses are designed to endure the rough conditions of abrasive slurries, ensuring long-lasting performance.

- Unparalleled Flexibility: Anaconda slurry hoses are noted for their flexibility, making installation and maneuverability effortless. This adaptability is vital for fitting different equipment setups or navigating obstacles in industrial settings.

- Vacuum Resistance: Engineered to maintain structural integrity under various vacuum levels, Anaconda slurry hoses effectively transport materials from source to destination without compromise.

- Enhanced Durability: Tailored to the specific needs of the substances they carry, these discharge hoses resist abrasion, chemicals, and weathering. The robust inner linings are built to withstand wear, erosion, and chemical degradation, while the outer layers offer additional protection against external elements.

- Multiple Applications: Anaconda industrial dredging and slurry hoses are available in various sizes and diameters and are designed to meet diverse flow rates and suction needs, optimizing suction performance and minimizing pressure drops.

Explore the range of Slurry and Dredge Hoses today with Pump and Dredge Hub – your gateway to reliable and efficient fluid handling solutions in Libya.

Enhancing Operations with Anaconda Slurry Hose Benefits

Anaconda industrial discharge and slurry hoses stand out as indispensable tools in industries like mining, dredging, construction, and chemical processing. They excel in handling abrasive and viscous materials in liquid form or slurry, a daily challenge in these sectors. Their meticulous design is a testament to their ability to manage the demanding conditions of slurry transfer, promoting efficient and reliable operations.

Construction and Design:

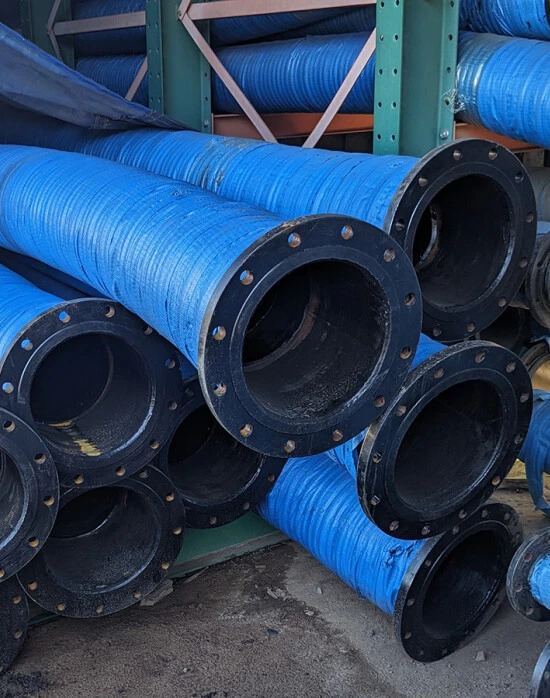

- Material Composition: Anaconda slurry hoses are made from high-quality rubber compounds and synthetic polymers. The inner lining is designed to withstand wear, erosion, and chemical degradation, ensuring durability and long service life. The outer layer offers protection against external elements, fortifying the hose against physical damage.

- Reinforcement: To prevent bursting under high pressure and enhance overall durability, these hoses are reinforced with layers of robust textile materials like polyester or aramid fibers. This not only maintains the structural integrity of the hose but also preserves its flexibility, which is essential for navigating complex and dynamic environments.

- Flexible Design: The inherent flexibility of Anaconda slurry hoses allows for easy maneuverability and adaptation to various system configurations and terrain changes, facilitating seamless connections within the slurry transport systems.

Operational Requirements:

- Abrasion Resistance: Tailored to confront the abrasive nature of slurry materials, these hoses are engineered to resist abrasion. This resistance extends the operational life of the hoses, reducing downtime and maintenance costs.

- Pressure and Vacuum Ratings: Anaconda slurry hoses are designed to handle slurry pumping systems’ intense pressures and vacuums. Adequate pressure ratings prevent hose failures, while effective vacuum resistance ensures that suction and discharge processes are carried out efficiently.

- Size and Diameter: The sizing and diameter of the hoses are critically matched to the flow requirements of each specific application, optimizing performance and reducing energy consumption within the slurry pumping systems.

By choosing Anaconda slurry and discharge hoses, industries gain a practical solution combining robust construction and operational efficiency. These hoses are specifically designed to meet the unique needs of demanding applications where slurry transport is prevalent, making them a valuable addition to any operation.

Key Applications of Anaconda Slurry Hoses Across Industries

Anaconda Pipe and Hose’s Slurry Hoses are expertly crafted to manage abrasive and high-solid content slurries, making them indispensable in various industrial sectors where such materials are frequently handled. Here’s a closer look at some of the key industries that rely on these robust hoses for their operations:

- Mining and Mineral Processing: In the mining sector, Anaconda Slurry Hoses are crucial for efficiently transporting mined materials, ores, and other mineral products within processing facilities.

- Agriculture: These hoses are used for applications such as transferring manure and liquid fertilizers, enhancing the efficiency of farming operations.

- Dredging and Marine: Anaconda Slurry Hoses are vital in dredging projects, where they are used to move sediments, sand, and debris from bodies of water to maintain waterways and harbors.

- Construction and Tunneling: In the construction industry, slurry hoses facilitate the movement of concrete, cement, and other slurry mixtures, which is critical during building and tunneling projects.

- Oil and Gas: These hoses are also employed in the oil and gas industry, particularly for transporting drilling mud, cuttings, and other slurries involved in exploration and production.

- Waste Management: Slurry hoses play a significant role in wastewater treatment and disposal by handling abrasive waste materials and sludge.

- Chemical Processing: These hoses transport abrasive chemicals and fluid slurries in chemical plants, ensuring safe and efficient process operations.

- Power Generation: Anaconda Slurry Hoses are used in power plants for critical tasks like ash handling and coal slurry transportation, contributing to these facilities’ operational efficiency.

- Pulp and Paper: These hoses handle various materials in the pulp and paper industry, including pulp, paper stock, and waste.

- Cement and Concrete Industry: Slurry hoses are essential in cement plants for transporting cement slurries and concrete mixtures, supporting continuous production.

The selection of a slurry hose in these industries depends on several factors, including the type and size of the solid particles, the required flow rate and pressure, and the chemical composition of the slurry. Anaconda’s range of slurry hoses offers solutions tailored to meet these diverse requirements, ensuring reliability and efficiency in challenging industrial environments.

CONTACT US

Discover the Strength of Anaconda Slurry Hoses

Explore the diverse applications of Anaconda Pipe and Hose’s Slurry Hoses, designed to handle the toughest industrial conditions across multiple sectors. From mining to waste management, our slurry hoses provide essential support for transporting abrasive and high-solid content slurries efficiently and reliably.

Pipes and Hoses

Please browse our extensive selection of resilient and durable pipes and hoses, engineered to withstand harsh conditions and available in various diameters and mounting styles across Libya. These products consistently deliver excellent performance in extreme operating environments. Discover custom solutions for your fluid transportation needs with our comprehensive product range today. Our pipes and hoses are built to last, ensuring long-term efficiency and cost-effectiveness for all industrial applications.